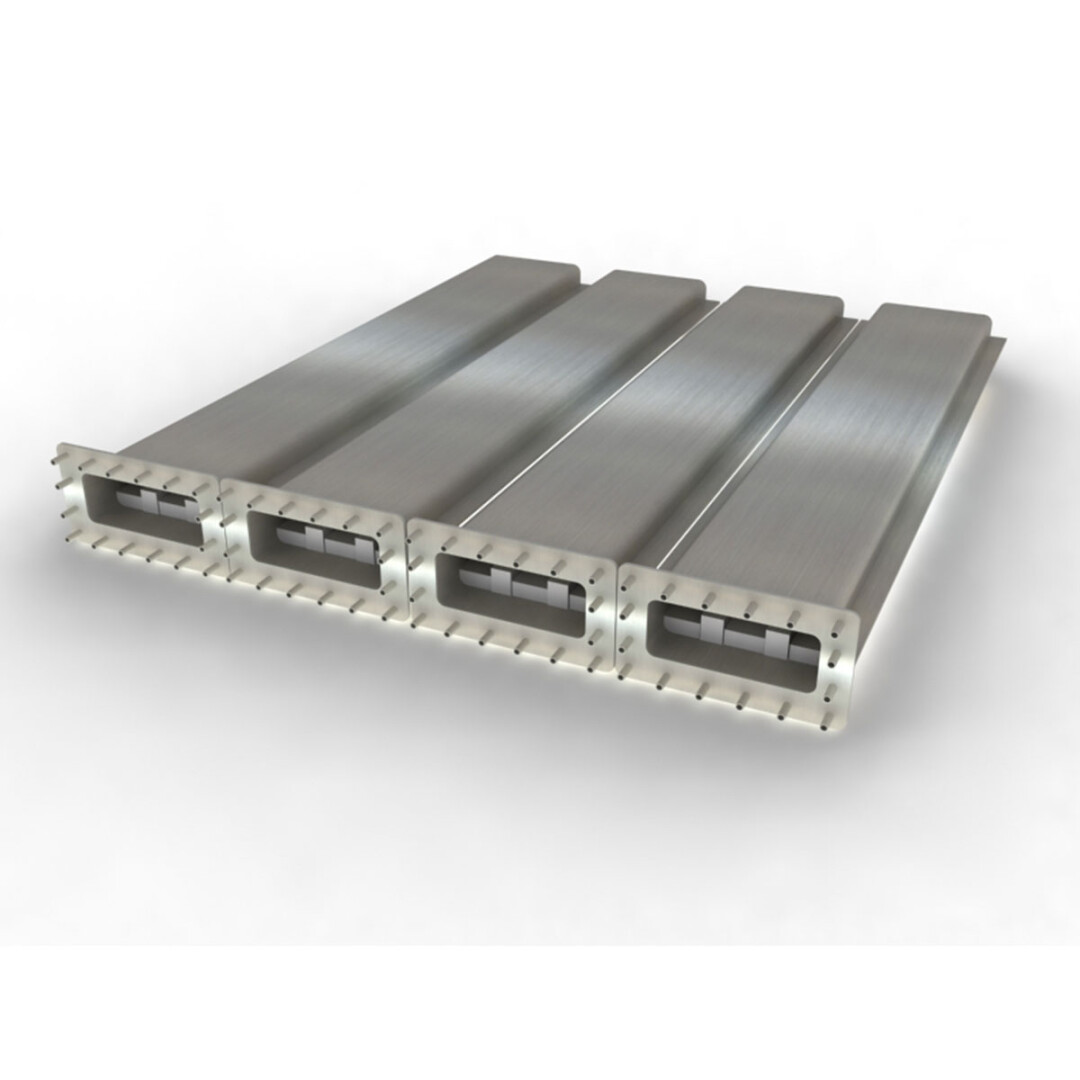

• Heat by conduction: a network of closed circuit pipes in which steam circulates.

• Smoke ducts of refractory bricks.

• Independent generous steam generators for any chamber.

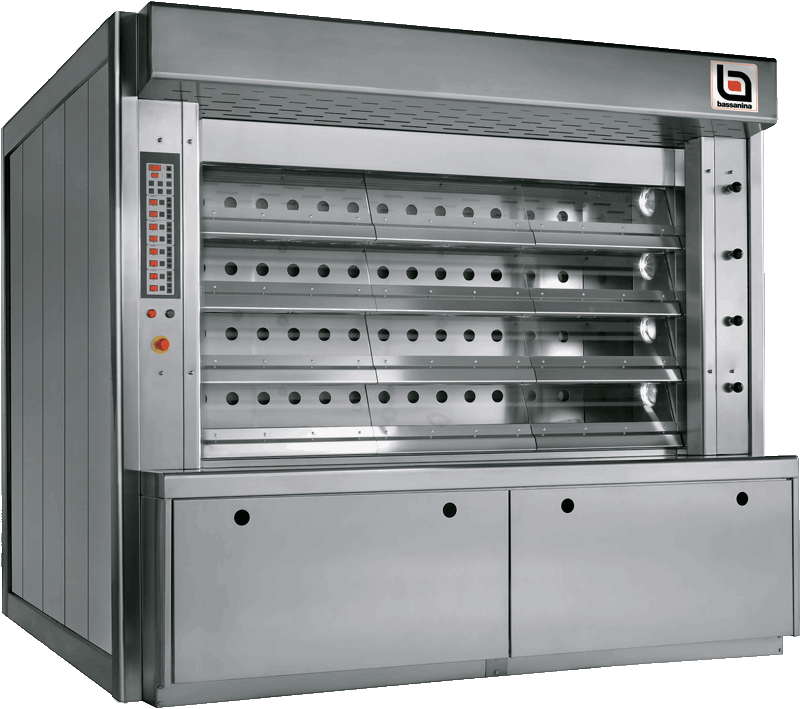

• Made of 1.0 to 3.0 mm gauge stainless steel AISI 430. 1.5 mm for the façade AISI 304.

• Baking floors made of 20 mm fireproof concrete plates, suitable for food use.

• Water manifold made of stainless steel.

• Balanced loading doors of thick temperate glass.

• Removable glass for easy cleaning.

• Multiple versions: mechanical, LCD or Touch Screen programmable panel.

• Available in liquid fuel and gas or solid wood, pellet.

• Furnished completely disassembled.

Products

TUBIX

STABLE BAKING

Tubix steam pipes deck oven is a static oven made of bricks and concrete.

The baking is exceptionally stable, homogeneous and spreads gently. The product rises with optimal fragrance and softness.

This oven offers high stability and heat efficiency, low consumption and extraordinary baking thrust.

Firm floor-base baking suited for great quantity and large size bread.

Key Features:

Unique Heating System. A dense network of closed-circuit pipes wraps around the baking chambers, ensuring even and consistent heat distribution.

Refractory Base Construction. Made of bricks and concrete with refractory materials in the basement, enhancing heat retention and efficiency.

Advanced Steam System. Independent steam generation for each deck, producing instant, high-volume steam for optimal bread crumb spring and crust formation.

Superior Baking Performance. Ensures stable, homogeneous baking with gentle heat spread, enhancing fragrance, softness, and rise in baked goods.

Energy Efficient. Designed for low fuel consumption while maintaining high thermal efficiency.

High-Capacity Baking. Ideal for large-scale production, especially for big loaves and high quantities, with excellent floor-base baking results.

Durable & Stable. Robust construction ensures longevity and consistent performance even under heavy use.

Why Choose Tubix Steam Pipes Deck Oven?

Perfect for Artisan & Large-Scale Baking. Delivers professional-grade results with superior crust and crumb structure.

Unmatched Steam Control. Independent steam per deck allow precise adjustments for different bread types.

Energy-Saving & Cost-Effective. Lower operational costs due to efficient heat retention and reduced fuel consumption.

Even Baking & Superior Heat Distribution. Eliminates hot/cold spots, ensuring uniformly baked products every time.

Ideal for Heavy-Duty Use. Built to handle high-volume baking without compromising quality.

Ideal for Bakeries focusing on rustic bread, soghdough, large loaves, and steam-dependent baked goods

"Game-Changer for Artisan Bread"

"Our TUBIX’s steam-pipe system delivers 28% better oven spring compared to conventional decks. The refractory base holds temperature so steadily that our sourdoughs now score 9/10 consistently in blind tastings."

— Luca F., Head Baker

"Energy Turnaround"

"After switching to TUBIX, our gas consumption dropped by 1,300€/month. The flue heat recovery system cutting idle energy waste by 30%."

— Hans K., Production Manager

"Seamless Relocation"

"Successfully relocated our Bassanina TUBIX deck oven to a new bakery location, demonstrating the oven's adaptability and the support from equipment specialists during the move.

Confirmed: there are no any change on technical performance post-move"

— E & L., Bakery Owners

Tubix or Zoom? If you are wonderig which is the most suitable solution for you between these two, take a look to this article and make up your mind!

http://www.bassanina.com/en-gb/News/Made-to-last-gb/tubix-or-zoom-which-is-the-best-for-you

Features

Safety systems

• Automatic safety thermostat.

• Emergency push button.

• Steam exhaust fan.

• Overpressure ducts damper.

• Overpressure doors damper.

• Microswitch on the chimney lock.

Performance

• Thermal efficiency combined with high energy saving.

• High performance steam device: high amount of steam and short recovering time.

• Silent and stable machine, no moving pari.

• Maximum working temperature of 300°C (572°F).

• Time of continuous running is 24/24h.

• Uninterrupted baking cycles without affecting bread's quality.

• Average gradient of temperature rise, around 2/3°C/min (3.6°-5.4° F/min).

• The temperature of external panels' surface is noi exceeding 25°C (77°F) the ambient temperature.

• AII technical parts are locateci on the front side. Easy access and maintenance.

• Free space around the machine is not requested.

• lnsulation with compressed panels and rock wool flocks.

• No toxic materials are employed.

Specifications

• 2,3 or 4 decks of 170mm high (210 mm, on request) with 2,3 or 4 doors.

• Deck depth: mm.1600/ 2000/ 2400/ 2800.

• Total baking surface area (Mq): from 7.90 to 27.80.

• Electric voltage: 400v/50-60hz/3ph+N+G - 220v/50-60hz/3ph+N+G - 220/1.

• Water connection: inlet 1/2’’, outlet 3/4''.

• Steam exhaust outlet: 42: 180 mm, 33/43: 260 mm, 44: 260mm.

• Smoke exhaust outlet: 42: 200 mm, 33/43: 220 mm, 44: 260 mm.

• 2-years guaranteed, 5-years on the steam pipes.

• 2,3 or 4 decks of 7" high (8,3", on request) with 2,3 or 4 doors.

• Deck depth: 62,9", 78,7", 94,5", 110,2".

• Total baking surface area (Ft 2): from 85 to 300.

• Electric voltage: 208v/60hz/3ph+N+G - 220v/50-60hz/3ph+N+G - 400v/50-60hz/3ph+N+G - 110/1 - 220/1.

• Water connection: inlet 1/2’’, outlet 3/4''.

• Steam exhaust outlet: 42: 7". 33/43: 10". 44: 10".

• Smoke exhaust outlet: 42: 8". 33/43: 9". 44: 10".

• 2-years guaranteed, 5-years on the steam pipes.

MODEL S:

They have a multiple steamer located Inside the chamber.

2 for each deck, 1 for each door.

The S.750 model has three doors and three steamers.

Baking quality

• Absolutely uniform heat distribution.

• Even bake and perfect coloured baked goods.

• Fragrance, volume and softness to all types of bread.

• Excellent developed from de soil. The generous crust keeps aromas and helps for a longer conservation.

• Excellent crust. Shiny and homogenous thickness.

• Excellent texture. Bread well developed.

| MODEL | DECKS | DOORS | BAKING SURFACE | OUTSIDE DIMENSIONS | CHAMBER DISTANCE FROM THE FLOOR | POWER | WEIGHT INSTALLED | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NR | NR | MQ | MM | MM | MM - W x L x H + H1 | I MM | II MM | III MM | IV MM | KW | KCAL/H | KG | |

| 420 | 4 | 2 | 7.9 | 1600 | 1240 | 1840 x 2870 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 70.000 | 8900 |

| 421 | 4 | 2 | 9.9 | 2000 | 1240 | 1840 x 3270 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 85.000 | 9300 |

| 422 | 4 | 2 | 11.9 | 2400 | 1240 | 1840 x 3670 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 95.000 | 9700 |

| 420S | 4 | 2 | 7.9 | 1600 | 1240 | 2075 X 2870 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 70.000 | 8900 |

| 421S | 4 | 2 | 9.9 | 2000 | 1240 | 2075 X 3270 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 85.000 | 9300 |

| 422S | 4 | 2 | 11.9 | 2400 | 1240 | 2075 X 3670 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 95.000 | 9700 |

| 420S.800 | 4 | 2 | 10.3 | 1600 | 1616 | 2460 X 2870 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 80000 | 9700 |

| 421S.800 | 4 | 2 | 12.9 | 2000 | 1616 | 2460 X 3270 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 85000 | 10100 |

| 422.S800 | 4 | 2 | 15.5 | 2400 | 1616 | 2460 X 2670 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 115000 | 10500 |

| 330 | 3 | 3 | 8.9 | 1600 | 1860 | 2460 X 2870 x 2200 + 330 | 1000 | 1250 | 1500 | 1.4 | 75.000 | 8500 | |

| 331 | 3 | 3 | 11.2 | 2000 | 1860 | 2460 X 3270 x 2200 + 330 | 1000 | 1250 | 1500 | 1.4 | 90.000 | 8900 | |

| 332 | 3 | 3 | 13.4 | 2400 | 1860 | 2460 X 3670 x 2200 + 330 | 1000 | 1250 | 1500 | 1.4 | 100.000 | 9300 | |

| 430 | 4 | 3 | 11.9 | 1600 | 1860 | 2460 X 2870 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 90.000 | 9700 |

| 431 | 4 | 3 | 14.9 | 2000 | 1860 | 2460 X 3270 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 110.000 | 10100 |

| 432 | 4 | 3 | 17.9 | 2400 | 1860 | 2460 X 3670 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 120.000 | 10500 |

| 433 | 4 | 3 | 20.9 | 2800 | 1860 | 2460 X 4070 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 130.000 | 10900 |

| 242 | 2 | 4 | 11.9 | 2400 | 2480 | 3080 X 3670 x 2200 + 330 | 1000 | 1250 | 1.4 | 75.000 | 9700 | ||

| 432S.750 | 4 | 3 | 17.9 | 2400 | 2250 | 3080 X 3670 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 135000 | 11300 |

| 433S.750 | 4 | 3 | 20.9 | 2800 | 2250 | 3080 X 4070 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 155000 | 11700 |

| 440 | 4 | 4 | 15.9 | 1600 | 2480 | 3080 X 2870 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 125.000 | 10500 |

| 441 | 4 | 4 | 19.8 | 2000 | 2480 | 3080 X 3270 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 130.000 | 10900 |

| 442 | 4 | 4 | 23.8 | 2400 | 2480 | 3080 X 3670 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 150.000 | 11300 |

| 443 | 4 | 4 | 27.8 | 2800 | 2480 | 3080 X 4070 x 2200 + 330 | 850 | 1100 | 1350 | 1600 | 1.4 | 160.000 | 11700 |