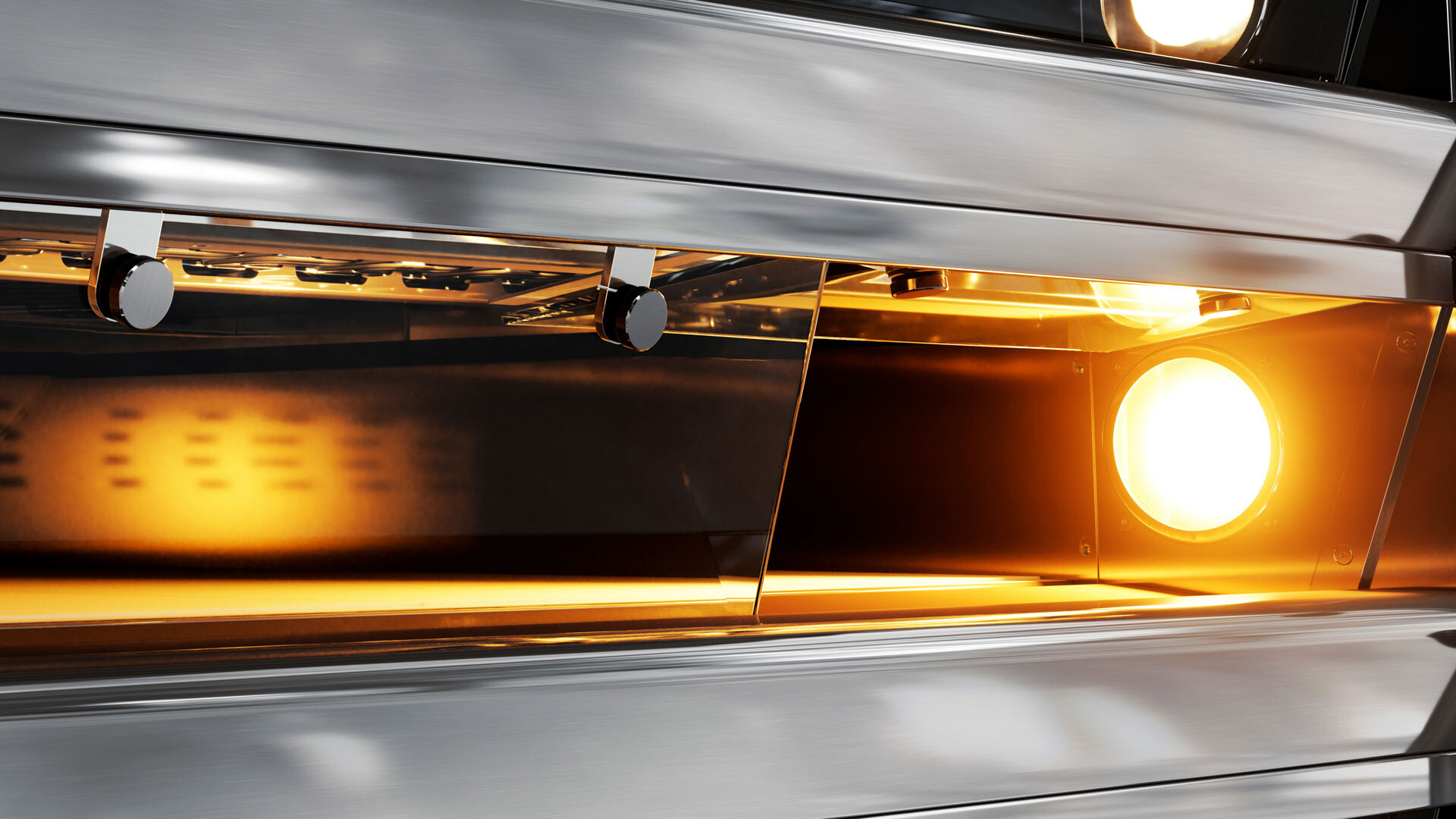

• Heat by conduction: armored heating elements with front access.

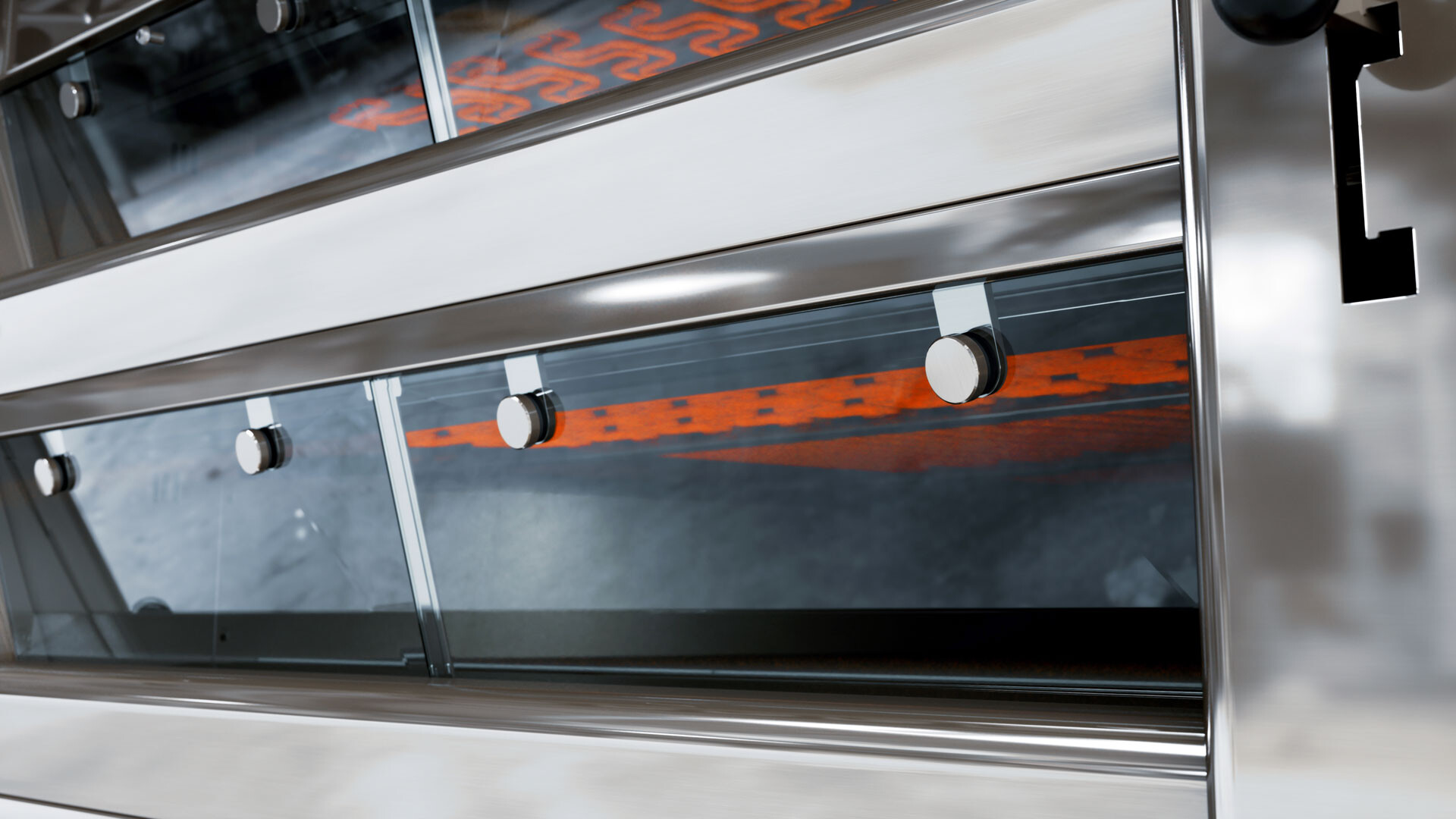

• 4 overlapping baking chambers.

• Independent steam generators for any deck.

• Made of 1.0 to 3.0 mm gauge stainless steel. 1.5 mm for the façade.

• Armored tubular heating elements made of AISI 309 stainless steel.

• Baking floors made of 20 mm fireproof concrete plates, suitable for food use.

• Water manifold made of stainless steel.

• Loading doors of thick temperate glass; removable for easy cleaning.

• Assembled delivery, ready for quick installation.

• "Effortless Positioning". Easily moved using a standard manual pallet truck

Products

ECOPOWER

THE ELECTRIC DECK OVEN

ECOPOWER is a static electric deck oven powered by clean electricity, producing no combustion fumes.

Thanks to its smart technology SBS (Smart Baking System) and armored heating elements, ECOPOWER ensures efficient energy use by adjusting heat intensity according to temperature demands.

Zero Emissions. Fully electric operation with no combustion fumes.

Versatile Baking. Ideal for:

Artisan bread (sourdough and traditional breads);

Pastries (cakes, pies, baklava);

Savory goods (focaccia, soft or crust pizza).

Modular Design. Freestanding structure with stainless-steel baking chambers with independent temperature setting (multi-decks flexibility).

Separate steam injection per deck (adjustable humidity levels).

Smart Baking System. Armored heating elements with dynamic power modulation (wattage adjusts to temperature needs).

Why Choose ECOPower?

Solid, durable structure made of stainless steel. Designed for easy movement and repositioning without the need for disassembly.

Energy Efficiency. Eliminates wasteful peaks by maintaining average required output during baking cycles.

Versatility. Power easily adjustable to suit your needs and expectations even during the baking cycle.

Find the ideal settings to enhance the development, aroma and softness or fragrance of the product.

"The Electric Revolution We Needed"

"After switching to ECOPOWER, our bakery cut carbon emissions by 4.2 tons annually while maintaining perfect hearth bread quality.

The instant steam response (0→100% humidity in 7 sec) gives our sourdough that iconic blistered crust."

— Paolo V., Director

"The independent deck controls let us bake croissants at 175°C and bread up to 290°C simultaneously. No more batch delays – just consistent results across all products."

— Carlos M., Pastry and bakery chef

Features

Safety systems

• Automatic safety controls of temperatures.

• Emergency switch.

• Steam exhaust fan.

• Overpressure breather.

• Loading/unloading suction hood.

• Automatic safety controls of temperatures.

• Emergency switch.

• Steam exhaust fan.

• Overpressure breather.

• Loading/unloading suction hood.

• CE. ETL ready.

Performance

• Thermal efficiency combined with high energy saving.

• High performance steam device per deck: high amount of steam and short recovering time.

• Silent and stable machine, no moving part.

• Maximum working temperature of 572°F.

• Time of continuous running is 24/24h.

• Uninterrupted baking cycles without affecting bread’s quality.

• Average gradient of temperature rise, around 5.4/7.2°F/min.

• All technical parts are located on the front or up side. Easy access and maintenance.

• Free space around the machine is not requested.

• Insulation with compressed panels and rock wool flocks.

• Power and its distribution in % adjustable.

Specifications

• 4 baking chambers: 3 of 6.7" high; the one, on the top, of 8.25".

• Decks available in the following dimensions (inch):

Single door 31.5x47.25; 31.5x63; 31.5x78.75.

Double doors 47.25x31.5, 47.25x47.25, 47.25x63, 47.25x78.75, 47.25x94.50.

• Total baking surface area (sqft): from 41.30 to 128.

• Electric voltage: 208v/60hz/3ph+N+G - 220v/50-60hz/3ph+N+G - 400v/50-60hz/3ph+N+G

• Water connection: inlet 1/2’’, outlet 3/4’’.

• Steam exhaust outlet: 7".

• Multiple versions: touch screen and "smart" with PLC control.

• 2-years guaranteed.

Baking quality

• Personalized adjustment of baking, ceiling and floor.

• Absolutely uniform heat distribution.

• Even bake and perfect coloured baked goods.

• Fragrance, volume and softness to all types of bread.

• Excellent developed from de soil. The generous crust keeps aromas

and helps for a longer conservation.

• Excellent crust. Shiny and homogenous thickness.

• Excellent texture. Bread well developed.

| 1 DOOR OF 31.5" | BAKING SURFACE |

EXTERNAL DIMENSIONS |

INTERNAL DIMENSIONS |

POWER | INSTALLED POWER |

SBS POWER |

WEIGHT |

|---|---|---|---|---|---|---|---|

| MODEL | FT2 | A x B x H inch | Ac x Bc x Hh (x3) - Hc (x1) inch | Kw/Hz/Ph | KW | KW | LB |

| 812 | 41.33 | 52.75 x 89,37 x 95 | 32.36 x 47.71 x 6.7-8.25 | 208/60/3 | 35 | 22 | 4630 |

| 816 | 55,11 | 52.75 x 105.11 x 95 | 32.36 x 63.46 x 6.7-8.25 | 208/60/3 | 46 | 29 | 5295 |

| 820 | 68,89 | 52.75 x 120.86 x 95 | 32.36 x 79.21 x 6.7-8.25 | 208/60/3 | 55 | 35 | 5955 |

| 2 DOORS OF 23.625" | BAKING SURFACE |

EXTERNAL DIMENSIONS |

INTERNAL DIMENSIONS |

POWER | INSTALLED POWER |

SBS POWER |

WEIGHT |

|---|---|---|---|---|---|---|---|

| MODEL | FT2 | A x B x H inch | Ac x Bc x Hh (x3) - Hc (x1) inch | Kw/Hz/Ph | KW | KW | LB |

| 1208 | 41.33 | 69.25 x 73.62 x 95 | 47.70 x 31.70 x 6.7-8.25 | 208/60/3 | 37 | 23 | 4630 |

| 1212 | 62.00 | 69.25 x 89.37 x 95 | 47.70 x 47.44 x 6.7-8.25 | 208/60/3 | 48 | 28 | 5750 |

| 1216 | 82.67 | 69.25 x 105.11 x 95 | 47.70 x 63.18 x 6.7-8.25 | 208/60/3 | 62 | 37 | 6620 |

| 1220 | 103.33 | 69.25 x 120.86 x 95 | 47.70 x 78.93 x 6.7-8.25 | 208/60/3 | 75 | 45 | 7500 |

| 1224 | 124 | 69.25 x 136.61 x 95 | 47.70 x 94.68 x 6.7-8.25 | 208/60/3 | 86 | 50 | 8380 |

SBS – Smart Baking System

The SBS Revolution: Perfect Baking with Minimal Consumption.

No more waste, just results.

High-precision performance. Zero unnecessary consumption.

How it works:

The Smart Baking System (SBS) redefines energy efficiency through:

• Pulse Technology – Eliminates power spikes by maintaining an optimized average consumption throughout the entire baking cycle.

• Dynamic Adaptation – Uses only the energy strictly needed, adjusting in real time:

• Power demand (up to 40% less vs. traditional ovens).

• Electrical load (lower amp draw).

Key Benefits:

• Energy Savings – Eliminates waste through perfect synchronization with the baking phases.

• Simplified Connectivity – Requires electrical lines with lower capacity (lighter infrastructure).

• Outstanding Stability – Maintains temperature with high precision.

Why Choose SBS?

Ideal for:

• Labs or facilities with limited power availability.

• Companies focused on sustainability.

• Multiple installations (reduced total load).

Important Note:

The SBS system is applicable per single deck. We recommend proceeding with installation including a 20% capacity margin, to ensure adequate flexibility for managing any unforeseen issues.