News

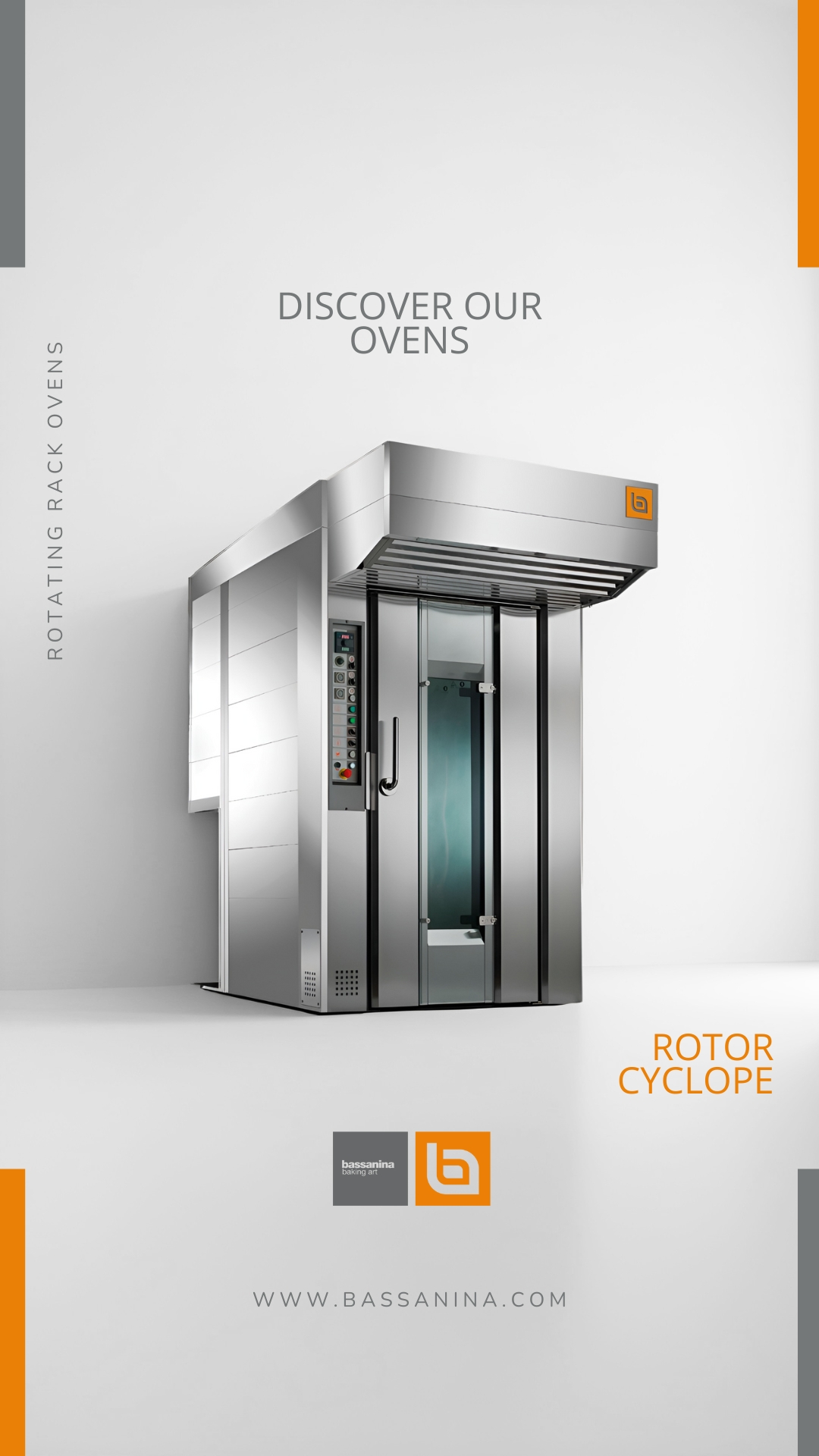

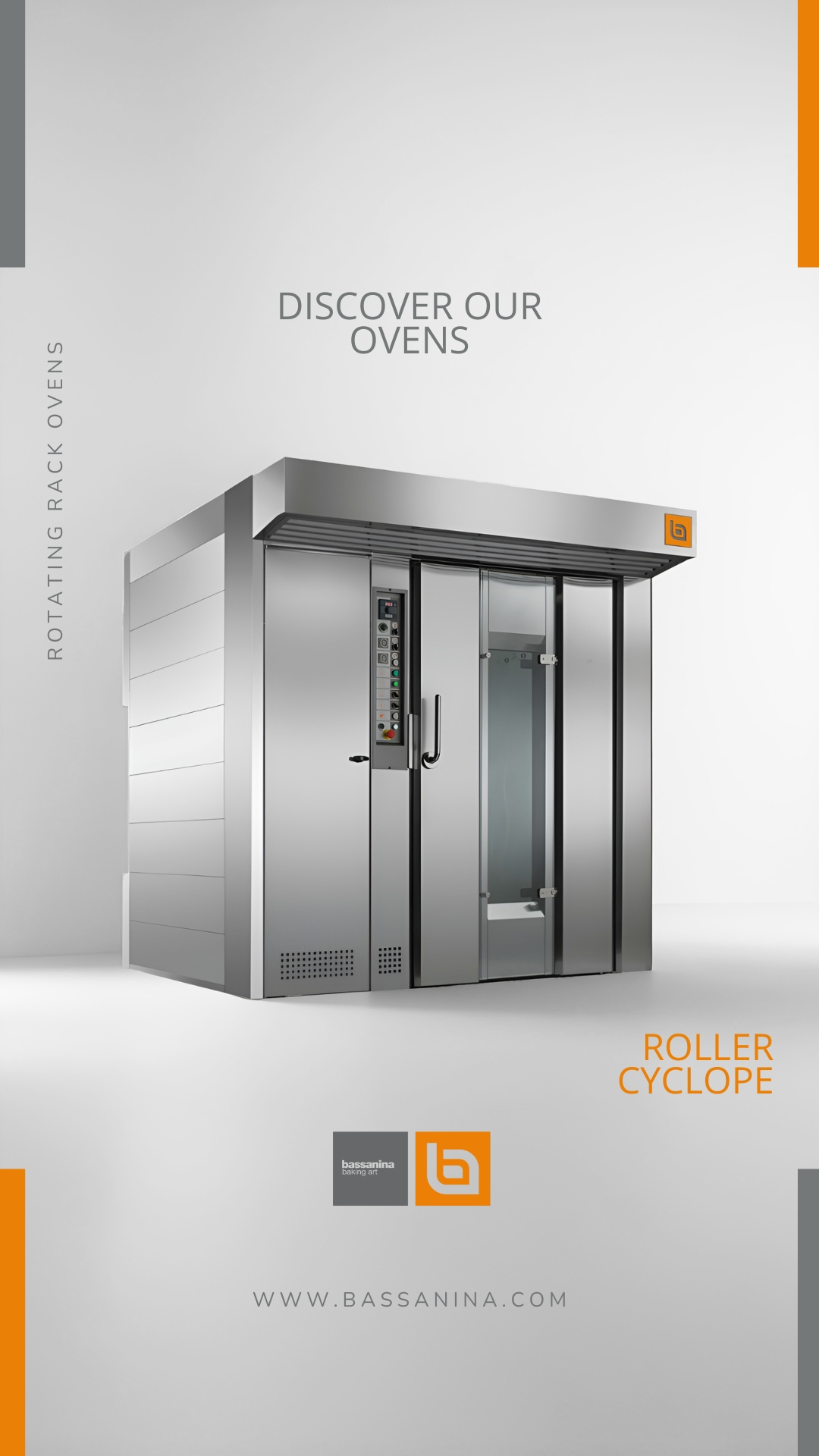

ROLLER.01 – ROTATING ROTOR RACK OVEN

ROLLER is a convection oven, equipped with forced air circulation and rotating rack. Its versatile nature makes it suitable for several types of bread and pastry products, both small and big-sized. It is provided with front burner and heat exchanger, in order to allow the alignment of various working units, by supporting common baking needs.

The high amount of steam during the baking process, grants even bake, homogenous crust and excellent texture. All its parts are joined with nuts and bolts, to offer superior performance in relation with thermal expansion phenomena, by assuring extended durability and working life.

ROLLER is the answer to the big market users in terms of strength, longevity and simplicity. Baking without compromise.

- STRUCTURE

Back side heat exchanger. The oven is made of 1.0 to 4.0 mm gauge stainless steel,

while its façade of 1.5 mm gauge sheet steel. The skillful use of different sheet metal gauges and the special bending system employed, plus the exclusive coupling system for individual components, reduce heat losses and optimize heat dispersion.

Moreover, since all its parts are fixed with screws, by the constant thermic dilatation, this system is more reliable and guarantees more durability and longevity. - HEAT EXCHANGER

Made of 2 mm gauge AISI 310 temperature-resistant steel. The heat exchanger is where combustion occurs and where the air is heated before coming into contact with the product. The heat exchanger is located on the rear left side of the oven (front left side for the Roller) and it is composed of tubes with the function of increasing the heat exchanger surface area. The combustion gases go through the exchanger – 4 turns – until the chimney exit. Its design grants long-lasting working life, by representing the results of experience and know-how. - STEAM DEVICE

The steamer is composed by easy-cleaning, removable and alternately overlapped elements. Every component is filled up with 280-gr-cast-iron spheres. Water is provided from two different points and it flows downwards, by wrapping up every single sphere. When entering the steamer, it is organized by an electric valve and supervised by a measurement device; a proper basin has the purpose to collect and remove the exceeding amount of water. The steamer is located inside the baking chamber, close to the heat exchanger and behind its protective panel.