News

TUBIX.04 – STEAM DEVICE

INDEPENDENT STEAM GENERATION SYSTEM

Each baking chamber is equipped with a dedicated, high-performance steam generator, engineered to deliver immediate, consistent, and high-volume steam. This advanced system is essential for controlling crust development, optimizing oven spring, and enhancing both the visual appeal and shelf life of baked products.

High-Capacity Steam Inlets

Steam is injected into the chamber through multiple nozzles, strategically distributed to ensure uniform steam coverage from the moment baking begins. Each inlet is managed by a timed solenoid valve, adjustable via a programmable controller. This allows fine-tuned steam injection according to dough type and baking phase.

Construction & Materials

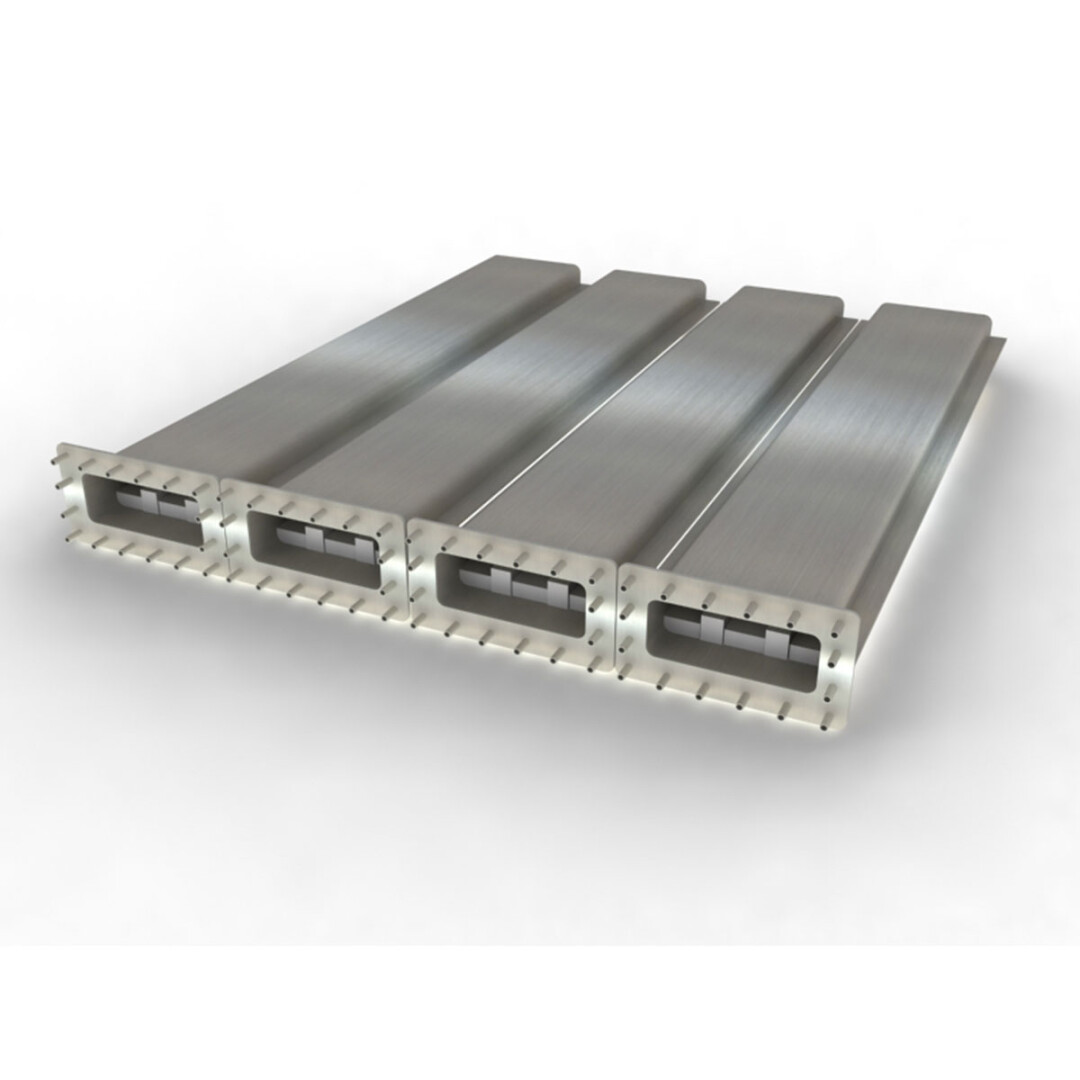

The steam generators are constructed from a robust iron (Fe) housing with a 10 mm wall thickness, designed to withstand high thermal and mechanical stress. Internally, they feature solid steel section bars (30×40 mm) that maximize thermal mass and heat retention. Each generator weighs approximately 200 kg, ensuring an ample thermal reserve for consistent steam production.

The refractory concrete covers all the devices to keep them hot.

Refractory Concrete Thermal Insulation

All steam-generating devices are encased in high-density refractory concrete, specifically formulated to withstand extreme temperatures and thermal cycling. This layer of insulation serves a dual function: it preserves the internal thermal energy of the steam generators, maintaining them at optimal operating temperature, minimizes heat dispersion to the surrounding. As a result, the system achieves superior energy efficiency, rapid steam recovery between cycles, and reduced fuel consumption.

Steam-On-Demand Capability

Integrated within the oven’s pipe-based heat distribution system, the steam generators maintain instant readiness. Heat from the circulating pipes ensures rapid vaporization of water upon injection, generating dense, saturated steam precisely when required.

Functional Benefits in Baking

Steam plays a pivotal role in the early stages of baking:

Delays crust formation, keeping the dough surface soft and elastic to promote ideal expansion.

Coagulates surface starches, producing a glossy, golden-brown crust.

Improves aroma and moisture retention, preserving flavor and extending freshness.

Prevents surface imperfections, reducing risks such as blistering and cracking.

Each deck also includes an independent exhaust valve, enabling precise steam evacuation as needed—crucial for crust definition and moisture control in the final bake phase.