News

TUBIX.03 – PIPE BANDS

Steam pipes ovens

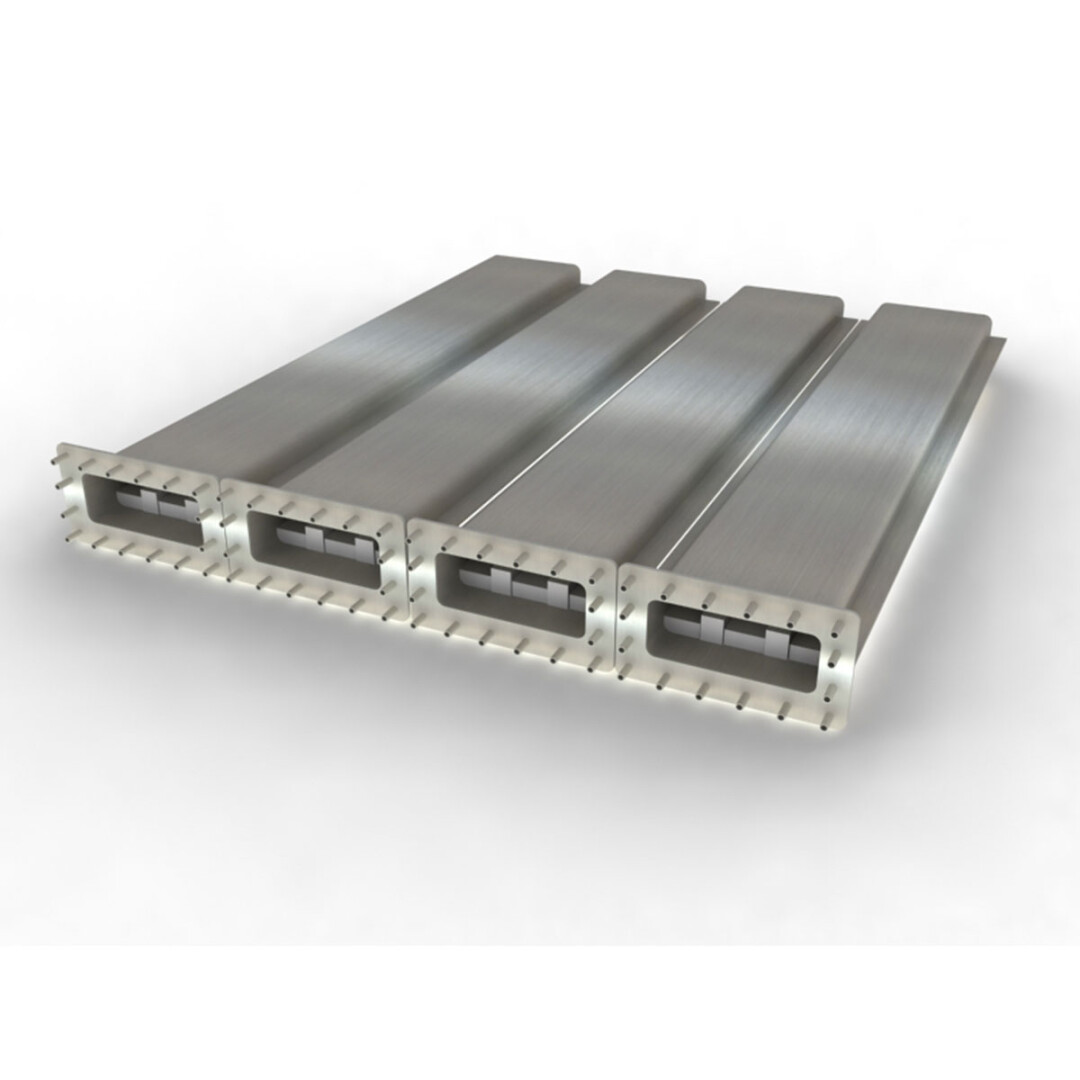

PIPE SYSTEM – CORE THERMAL TECHNOLOGY

The pipe system represents the true thermal heart of the oven — a high-performance heat engine responsible for delivering and distributing energy to the baking chamber with exceptional precision. This system enables uniform and stable heat diffusion, ensuring consistent and gentle baking throughout the entire oven cavity.

Independent Thermal Circuits

Each pipe functions as a self-contained thermal circuit, partially filled with demineralized water. Upon heating, this water transforms into steam, creating internal pressure that enhances heat transmission. Approximately 50% of the pipe’s volume is occupied by water in its liquid or vapor phase during operation. This controlled vaporization process ensures thermal consistency and a highly stable temperature profile across all baking surfaces.

Heat Distribution by Conduction

A dense network of interconnected ring circuits surrounds the baking chamber. These rings are directly welded or clamped in thermally optimized contact, allowing for efficient heat transfer by conduction to every point of the chamber. The system’s slow heat release and high thermal inertia are critical to achieving the characteristic gentle and gradual baking typical of wood-fired and steam tube ovens.

Engineering & Materials

The pipes are constructed from cold-drawn, high-endurance steel, manufactured without welds to eliminate weak points and enhance thermal reliability. Each unit undergoes individual testing in compliance with UNI 663/68 standards to ensure pressure resistance and structural integrity.

-

External Diameter: 27 mm

-

Wall Thickness: 4 mm

-

Material: Weldless cold-drawn steel

-

Water Volume per Tube: Precisely calibrated for optimal vapor pressure

-

Spacing and Layout: Engineered for homogeneous thermal coverage

The geometry, spacing, and volume of each pipe have been carefully developed through extensive in-house testing and application experience. This proprietary configuration is key to the system’s thermal efficiency, mechanical durability, and baking performance.