News

ROTOR.02 – STEAMER WITH SPHERES

Steam Generation System with Cast-Iron Spheres – Innovation and Superior Performance

The new steam generator with spheres can transform 6 liters of water into steam in just 20 seconds, delivering 30% higher efficiency. This outstanding result ensures uniform and continuous steam distribution throughout the baking chamber, even during extended work cycles. The steam envelops the bread, enhancing the surface shine and promoting optimal development.

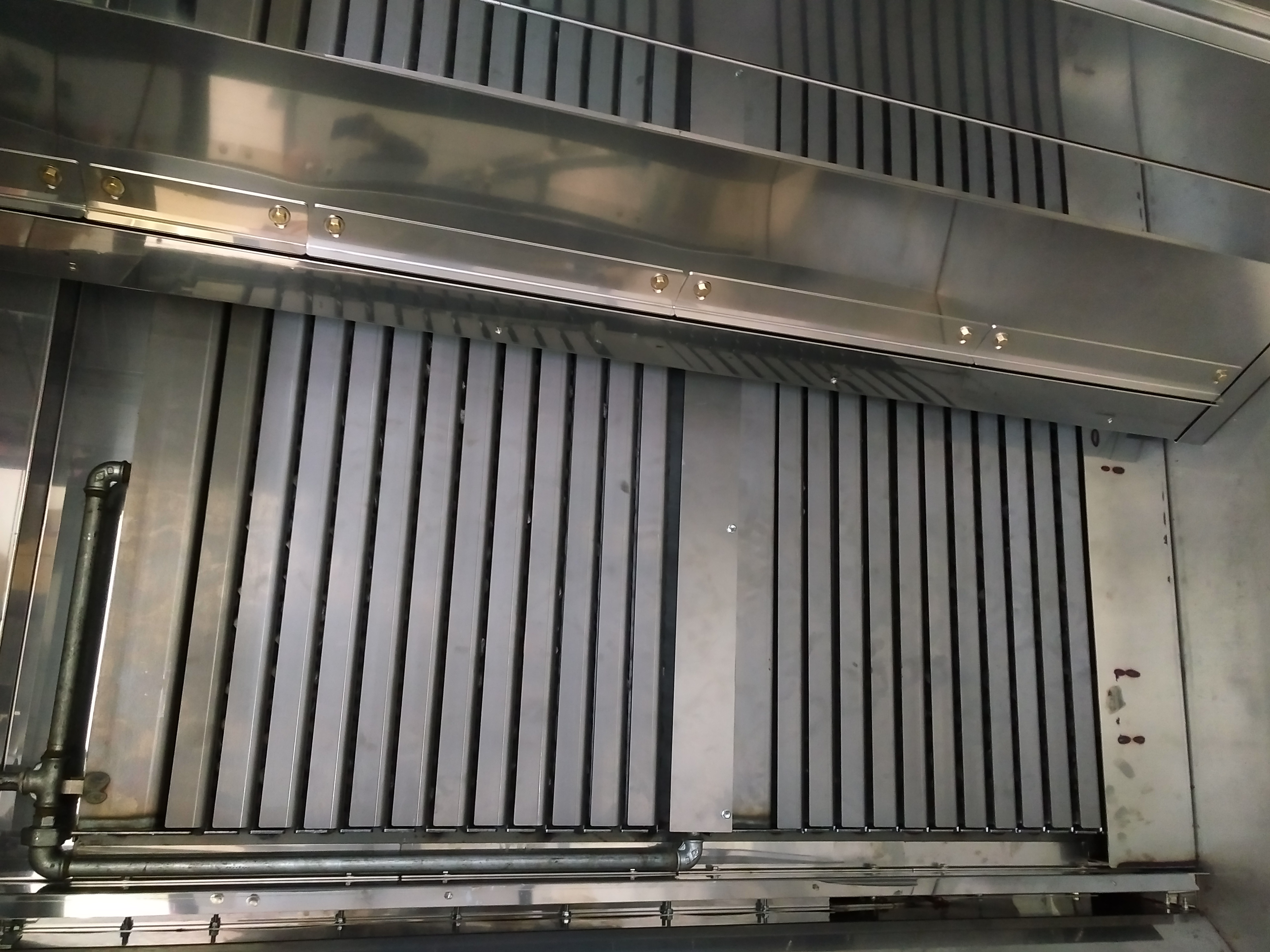

The generator is composed of removable, easy-to-clean components arranged in an alternating, overlapping design. Each element is filled with 280-gram cast-iron spheres, which allow for fast and efficient heat release.

Water is supplied from two separate inlets, flowing downward and enveloping each individual sphere. Upon entering the generator, the water flow is managed by an electric valve and monitored by a measuring device. A dedicated basin collects and drains excess water.

The steam generator is installed inside the baking chamber, at the hottest point, near the heat exchanger and protected by a drip-proof panel. This advanced system ensures a higher concentration of steam inside the chamber, meeting the expectations of even the most demanding customers in terms of quality and performance.

STEAM

Once the product is placed inside the oven, the steam condenses on its surface due to the temperature difference between the dough (25–30°C) and the baking chamber (200–270°C), forming a thin film. This film softens the dough and acts as a barrier to the release of carbon dioxide. As a result, the dough expands more effectively, giving the bread greater volume.

This thin layer of water slowly re-evaporates, absorbing heat and slowing down surface chemical reactions. This process allows for the formation of a thinner and less rigid crust.

Since Maillard and caramelization reactions are affected by humidity, the crust’s color varies according to the amount of steam present. Steam plays a critical role in determining the crust’s thickness, color, crispness, and flakiness.

A significant amount of instantaneous steam is essential for optimal crust baking. It accelerates the baking process by delaying crust formation and enhancing key characteristics such as thinness, shine, and golden color. The volume and speed of steam production also help prevent issues such as poor hydration, blistering, and cracking.

Why spheres?

The relationship between volume and surface area in a sphere is an important concept in physics, engineering, and thermodynamics, especially when it comes to heat exchange, as in the case of cast-iron spheres used in steam generators. This ratio increases linearly with the radius. Smaller spheres (with a reduced radius) have a lower volume-to-surface ratio, meaning more surface area per unit of volume.

This is essential in thermal exchange processes: more exposed surface area means greater heat transfer capacity. In the application of the steam generator: the 280-gram cast-iron spheres offer an excellent compromise between thermal mass (volume) and thermal exchange area (surface). A large number of small spheres increases the total surface area available for water contact, improving the speed of vaporization.

In summary, the volume-to-surface ratio of a sphere is essential for designing efficient thermal systems: more surface area per unit of volume means greater heat exchange efficiency.

Why multiple water inlets?

The water inlets must be divided and distributed in order to fully cover the steam chamber within a 6-second timeframe. The spheres are arranged alternately; water flows from above, envelops the first row of spheres, and cascades onto the second, continuing this way to the first collection tray. This tray is located halfway down the steam chamber and contains the second water inlet. From here, water flows down and envelops the second half of the chamber. The water descends simultaneously from both inlets. At the base, a small basin collects any excess water.

Why removable components?

For ease and speed of cleaning.

Limescale acts as a thermal insulator. When it deposits on the internal surfaces of the steam generator (particularly on heating elements and cast-iron spheres), it obstructs heat transfer between the metal and the water. This results in increased energy consumption to achieve the same performance and reduced steam production over longer times.

Limescale can block water pathways or compromise the homogeneity of the flow inside the generator, leading to irregular steam distribution in the baking chamber and inconsistent product quality (e.g., differences in bread crust).

If not removed, limescale deposits can cause localized corrosion where moisture accumulates, premature wear on components exposed to thermal stress such as valves, spheres, and sensors, and system malfunctions or failures.

Regular limescale removal is not just good maintenance practice but a necessary condition for ensuring high performance, energy efficiency, product quality, and long-term safety. Preventive descaling programs and the use of treated water are therefore strongly recommended.

Standard procedure for descaling the steam generator

Warning: Before beginning, ensure the oven and steam generator are completely turned off, disconnected from the power supply, and cooled. Always follow the manufacturer’s instructions.

Draining and inspection

Completely drain residual water from the system. Remove all removable parts (e.g., protective panels, cast-iron spheres, trays). Visually inspect for scale or encrustation.

Application of descaler

Prepare a solution with a professional descaling product, following the recommended dosages. Soak the steam generator circuit and its components with the solution. Allow to act for 30–60 minutes, depending on the level of scaling.

Rinsing

Completely drain the solution. Perform at least two rinse cycles with clean water to eliminate all chemical residues. If possible, briefly operate the system with clean water only to complete the internal cleaning.

Component cleaning

Clean the pipe system, trays, supports, cast-iron spheres, and other parts with brushes and descaling solution. Rinse before reassembly.

Final check

Reassemble all components. Run a test cycle to verify the proper functioning of the steam generation system.

Tools

Professional ecological descaling agent. Iron or brass brushes.