News

TUBIX.01 – STEAM PIPES DECK OVENS

The baking at the top. Tubix is a static steam pipes deck oven made of bricks and concrete.

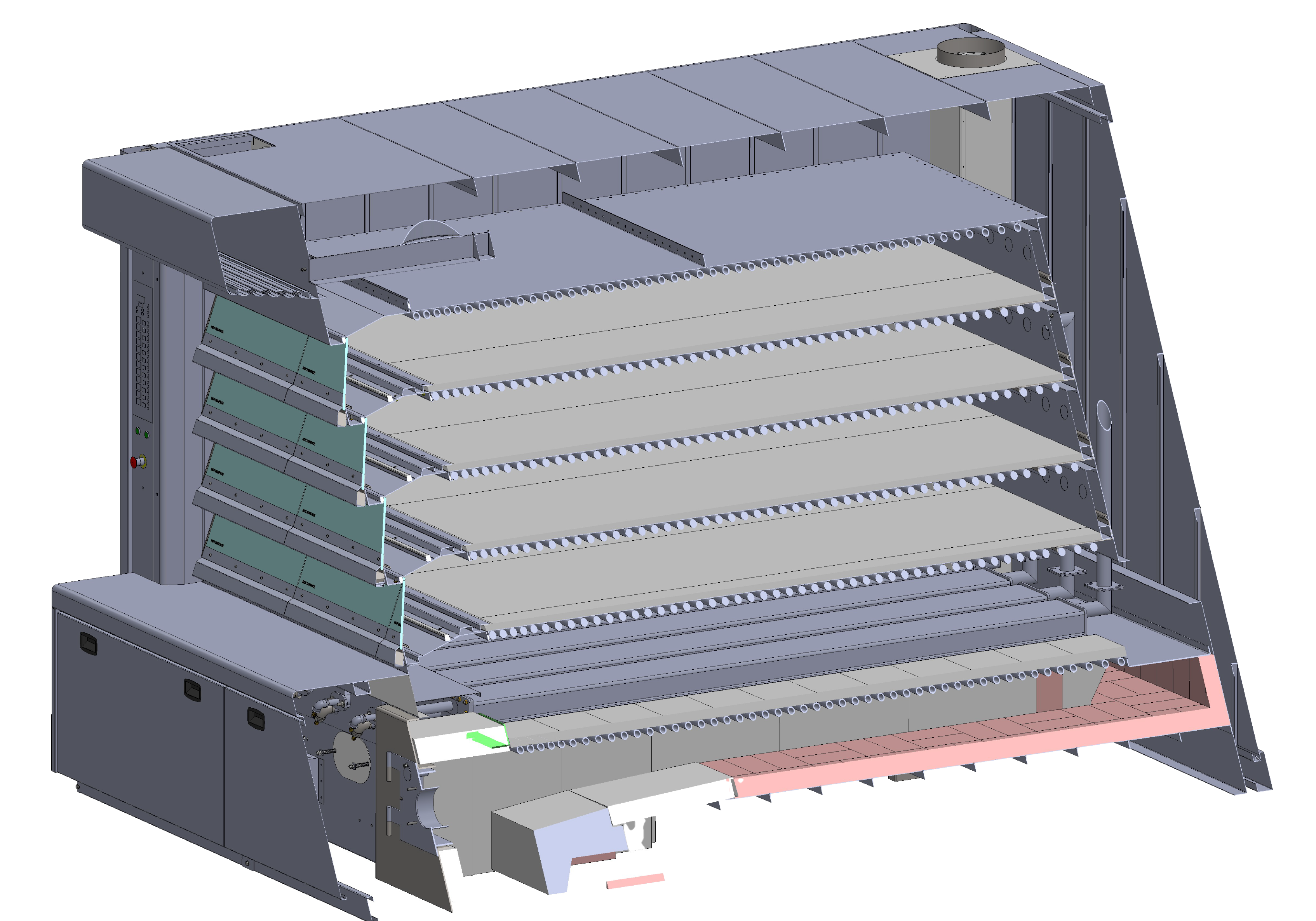

The chief characteristic is the heating system: a dense network of closed circuit pipes wraps and heats the baking chambers. The basement is made of refractory materials, where perfectly sized smoke ducts transmit the energy from combustions to the band of pipes. The powerful steam system, independent for each deck, provides the immediate expansion of the steam in large quantity.

The baking is exceptionally stable, homogeneous and spreads gently. The product rises with optimal fragrance and softness. This oven offers high stability and heat efficiency, low consumption and extraordinary baking thrust. Firm floor-base baking suited for great quantity and large-size bread.

- STRUCTURE

The oven is made of stainless steel with thickness of 1; 1,5, 2 or 3 mm. The façade of AISI 304 has a 1,5 mm thickness and inside every baking chamber is panelled with 1 mm stainless steel. The baking floors are made of 20 mm extremely dense (1.900 kg/m3) fireproof concrete plates. Capable of high heat storage, high mechanical resistance and an exclusive coating that allows easy maintenance. The applied materials are exclusively mineral, the sheets are hygienic and include no health-damaging substances. The loading doors are designed for the use of the proper conveyor belts. The opening is up-bottom. They are made in thick temperate glass, perfectly balanced by counter-weights, for fast opening and easy cleaning. The basement is a modular system made of thermic cement and refractory bricks that create the channels where hot smokes circulate. These ducts transmit the energy

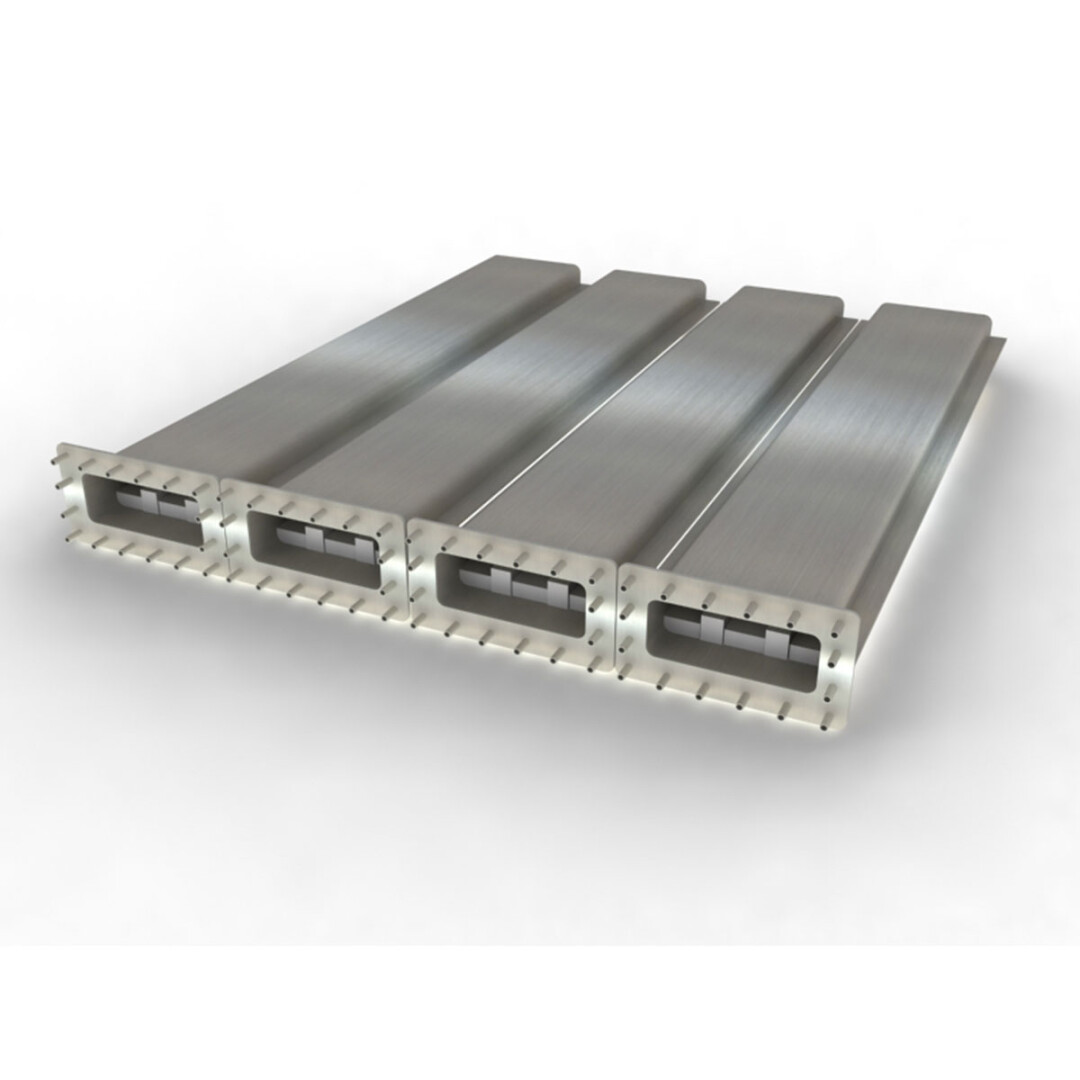

from the combustion to the band of pipes. The outside covering is made of stainless steel. - THE PIPES

The pipe bands are the real heart of the oven: the thermal “engine” that carries the heat to the baked products. The pipes diffuse an absolutely uniform heat in every part of the baking chamber. Their high storage capacity and the slow speed of heat release give its recognized gentle baking. Every tube constitutes a completely independent circuit, which contains demineralized water for about half of its volume that becomes steam during the heating process. A dense network of rings wraps the baking chambers and transmit heat by conduction to every single point. The pipes are made of high endurance steel, cold-drawn, without welding. They are tested one by one according to the rules UNI 663/68.

The diameter is 27 mm, the thickness 4 mm. The distance among each other, their position and the real volume of water inside, are the result of our experience and know-how. - STEAM DEVICE

Each baking chamber is supplied from independent powerful steam generators that guarantee repeated inlets of large quantities of steam. The water is sprayed inside from several points and is kept under strict control through a temporized solenoid valve adjustable with timer. Each chamber is supplied with an exhaust valve. Every steamer is made up an iron (Fe) box 1 cm. thick, filled with section bars 30x40. The weight is around 200 kg each one. This steam system, wrapped by the pipes, is always ready to produce great amount of steam. The steam keeps the dough’s skin elastic by allowing the bread to rise without tears. It causes the starch’s coagulation at the surface of the bread, by resulting in a more shiny look and a better conservation. The bread is more developed and keeps its look and aroma for longer.